Mercedes unibody repair leverages advanced digital technologies including laser scanning and 3D mapping for precise damage detection and accurate component alignment. This innovative approach facilitates complex repairs like paintless dent removal and enhances auto glass repair by identifying hidden structural issues.

Mercedes unbody repair techniques are undergoing a digital revolution. This article explores how advanced digital frame analysis is validating and enhancing the process, ensuring precision and structural integrity for these luxury vehicles. By leveraging cutting-edge technology, mechanics can now navigate complex repairs with enhanced accuracy, ultimately streamlining the entire Mercedes unibody repair ecosystem. Discover the mechanisms driving this validated approach to optimal vehicle restoration.

- <a href="#a-mechanism,-in-––––—-/-–––––––––––––––––––––––––––––-“>A mechanism, in /

<section id="a-mechanism,-in-––––—-/-–––––––––––––––––––––––––––––-“>

A mechanism, in

/

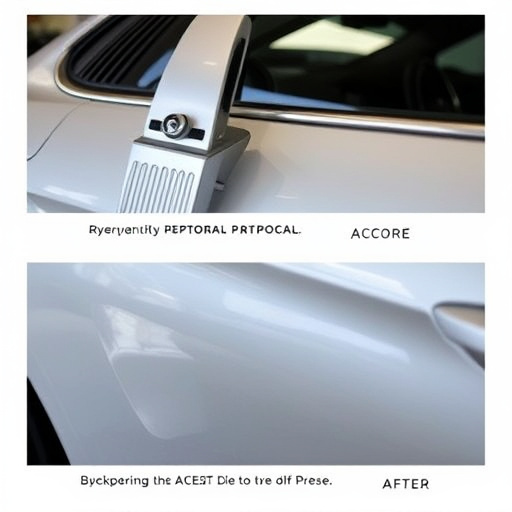

Mercedes unibody repair has evolved significantly with the advent of digital technologies. One revolutionary mechanism is the use of advanced frame analysis software to detect and measure structural damage with precision. This digital approach, often referred to as laser scanning or 3D mapping, provides a detailed, computer-generated model of the vehicle’s body, allowing technicians to pinpoint issues accurately. By comparing this data to original manufacturer specifications, repair teams can ensure that every component is aligned correctly during the restoration process.

This innovation in automotive restoration goes beyond simply fixing dents and scratches; it involves complex procedures such as paintless dent repair, where specialized tools are used to reshape metal without damaging the surrounding finish. Additionally, digital frame analysis aids in auto glass repair by identifying structural integrity issues that might be missed through traditional methods, ensuring both safety and longevity of the vehicle.

*